In Sweden, there is great potential for refining residues and wastes from forestry and forest-based industries. Several major initiatives are under way across the nation, whereby forest industry companies in collaboration with entrepreneurs are developing methods of processing wood-based raw materials into products that can be made into biofuels.

“The main challenge lies in making solid materials into liquids. A paradigm shift is under way right now, where we’re developing several different technologies for liquefying biomaterials into hydrocarbons, i.e. liquid fuels,” says Mattias Backmark, SVP Investor Relations at Preem.

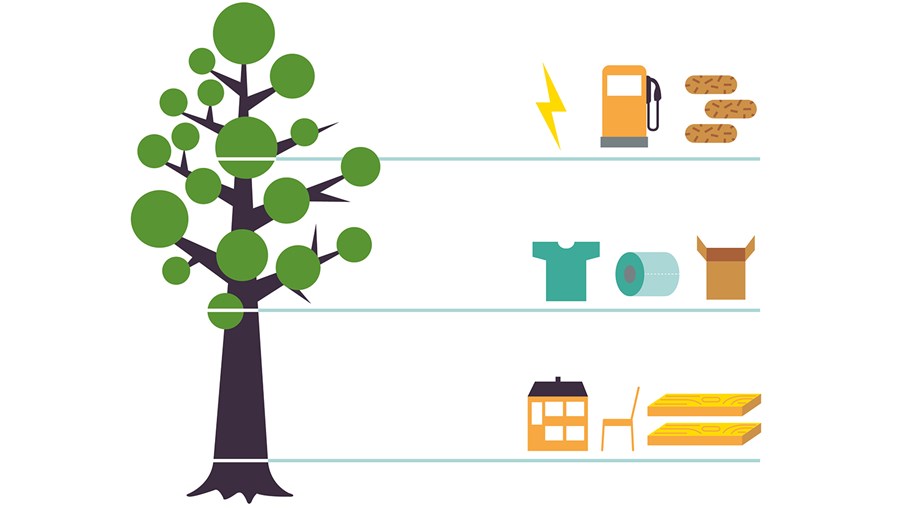

Biofuels from the forest

Forest company SCA is one of the players focusing heavily on making biofuels from the forest. Alongside energy company St1, they are looking into an investment in a new facility to increase the production of biofuel from tall oil, a by-product of sulphate pulp production. The long-term aim is to produce biofuels in such large volumes that it meets all the fuel needs of Sweden’s domestic aviation.

“We are convinced that sustainable, efficient forest management and the accompanying green products have a vital role to play in our society’s transition, and in helping to solve the climate threat we are all facing. We believe that biofuels and biochemicals from residuals in our value chain specifically will mean profitable business,” says Mikael Källgren of SCA.

Using the whole tree

The approach is called pyrolysis and entails rapidly heating solid matter like branches, roots and sawdust to vaporise it, and then turning it into a pyrolysis oil (or bio-oil), which is then refined into biopetrol and biodiesel. Alongside Preem, they are building a production plant in Gävle which will come online in 2021.

Start-up company RenFuel has a different method, which uses the lignin in a pulp mill’s black liquor, to make petrol and diesel that can be used in existing vehicles as they are. Working with Preem and Rottneros, they want to build the world’s first lignin plant for biofuels, located in Söderhamn. That too is planned to come online around 2021.

Another major player investing in a variety of ways to produce biofuel is the forest cooperative Södra. Alongside Statkraft, they have formed the company Silva Green Fuel, whose main task it is to find a technology for profitable production of future biofuels from forest raw materials. Their demo plant in Norway is developing both the processes and technologies for producing biofuels for different types of vehicles. . The methanol can be used both purely as a fuel, in producing biodiesel, and for mixing into existing petrol.

Reducing the climate impact of fossil fuels

Södra also supplies tall oil to SunPine, which in turn refines it into crude tall diesel. Mixing it into fossil diesel and petrol reduces the climate impact of today’s fossil fuels – something which SunPine are now investing even more in, with a SEK 350 million facility that will increase their production of tall oil by 50 per cent.

“We see huge potential in increasing the production of crude tall oil diesel, not by felling more trees but by utilising the existing flows in the pulp mills,” says Magnus Edin, former CEO of SunPine. “Making biofuels from tall oil is an important contribution to achieving the 2030 climate goals, but it’s also important to stress that we’re not competing with other biofuels. If future transport is to be sustainable, a combination of different fuel solutions is needed.”

According to SunPine’s own calculations, based on 2018 figures, their production following the investment could help to remove emissions from as much as ten per cent of all diesel vehicles in Sweden.