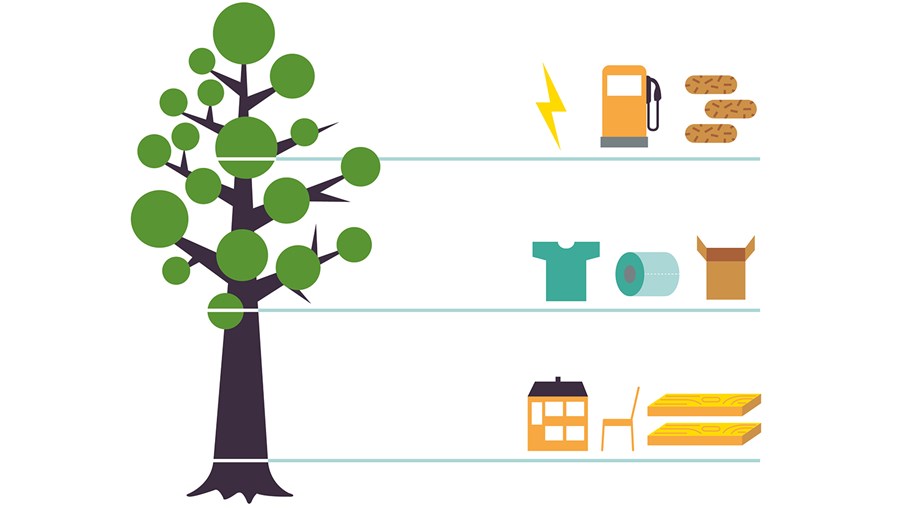

Textile pulp made of cellulose, also known as dissolving pulp, is an old technology that has recently attracted renewed interest and for which demand is growing rapidly. The need for more durable and fossil-free materials that can replace fossils is increasing. Textiles made of wood have the potential to be one way to replace oil-based textiles.

Today, the vast majority of clothing is derived from fossil materials such as oil. Cellulose fabric can be used as an alternative or as a complement to cotton and synthetic fibres made from fossil materials. On the right, you can read about some examples from our members.

How wood becomes textiles:

- Pulpwood is delivered from the forest to the sawmill.

- Wood is crushed and purified into a pure cellulose pulp, so-called dissolving pulp.

- Dissolving pulp is torn up, mixed with water and NMMO solvent, and becomes a viscous solution.

- The solution is pushed through a fine mesh to become fibres.

- A yarn is made from the fibres.

- Yarn is knitted or woven into a fabric that is dyed.

- Now we have a fabric that can be sewn into any garment!

Examples of wooden textiles:

-

Viscose

Produced mainly from cellulose from softwood and hardwood forest. The raw material may also come from other bio-based raw materials such as bamboo. Cotton can also be recycled into viscose.

-

Modal

Made in much the same way as viscose and has similar properties, but the fibres are stronger when wet. Modal is always made from beech wood.

-

Lyocell

Lyocell is the product of an environmentally friendly, circular manufacturing process. 99 per cent of the chemicals used in the production process can be reused and are biodegradable. Also known as Tencel.

Photo credit: Kerstin Jonsson

Photo: Kerstin Jonsson