The Swedish forest industry prioritises the working environment, gender equality, raw material use, and emissions to air and water. Sawmills and pulp and paper mills take a holistic view of their operations that incorporates employees, surrounding communities, resource use and environmental impact.

Equality and diversity

Competitiveness, growth and the working environment are all factors that are improved by diversity. The proportion of women in the Swedish forest industry must increase. This requires long-term work on norms, values and making educational paths and career development in the sector more attractive for all. The industry also has a clear stance against all forms of discrimination.

Safe working environment

Safe workplaces are attractive workplaces where people thrive and want to stay. Efforts in this area are conducted systematically with follow-up and reporting of incidents and risk assessments.

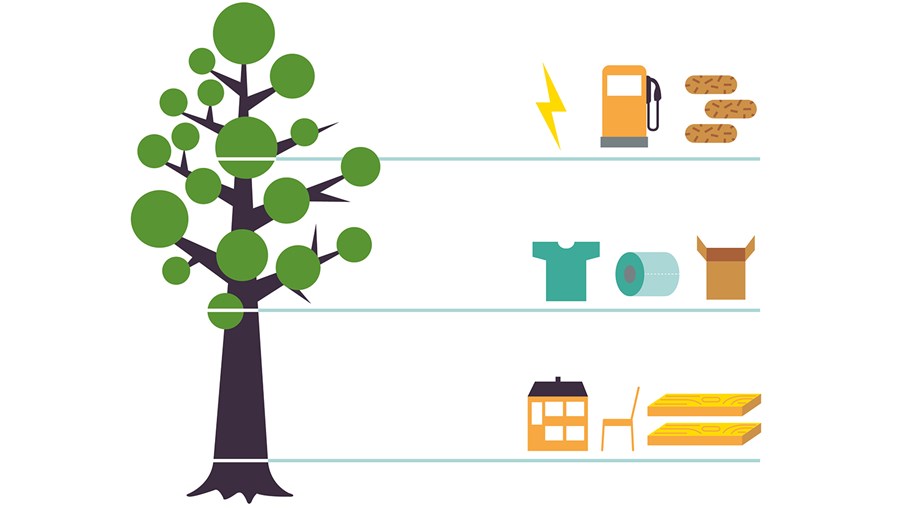

Raw material use

After a tree is harvested, the entire tree is used. The highest possible processing value determines what is produced from different parts of the tree. The strongest part of the trunk becomes timber for buildings and furniture. Thinner parts become pulp for the production of paper, cardboard and textiles. Tops, branches, and residual streams from the forestry industry go into products such as bioenergy, biofuels and other chemicals. Maximising the efficiency of raw material use is a top priority. In this, innovation and customer demand play key roles.

Environmental consideration

Environmental consideration has been a fundamental aspect of the forest industry’s sustainability work. Despite production having increased considerably, today’s emissions are a fraction of those of the 1970s. Read more here. (länk)

Emissions to the air

Having successfully reducing sulphur oxide emissions to almost zero, focus is now on using technology to reduce emissions of nitrogen oxides. Emissions of sulphur oxides decreased due to the transition to biofuels. The same fuels have also resulted in increased emissions of nitrogen oxides as they contain nitrogen.

Water use and emissions to water

Water is an important part of the production process. Sweden’s forest industry is striving to reduce its water use and make it more circular. The increased reuse of heated water also has a positive effect on energy consumption.

Pulp production in the 20th-century resulted in the release of wood fibres and environmental toxins into surrounding waterways. These have accumulated in fibre sediments and attracted emissions of environmental toxins from surrounding communities and industry. The latest research shows that the spread of environmental toxins from fibre sediments has decreased sharply and continues to decrease. Debate over whether fibre sediments should be left untouched or cleaned up persists. The Swedish Environmental Institute (IVL) has developed a control programme that the forest industry views positively.

Read more on the IVL website here.

Noise

Heavy industry runs 24 hours a day, every day of the year. This causes noise at all hours of the day and night, with noise at night typically being the most problematic. Despite industrial facilities often being built in areas prior to other urban development, there are several examples of reduced acceptance for noise levels and associated vehicular traffic. The industry has therefore worked for many years to limit noise levels. At the same time, the effects of such measures must always be balanced against their cost.

Odour

Wood can create odours that many people react to in the vicinity of industrial facilities. Associations with unattractive odours tend to be linked to pulp mills that use sulphite technology and sulphite mills. Nowadays, however, gases that cause these odours are collected and burned, and therefore today’s production processes smell less than they did in the past. If odours are created now, it is mainly due to a production problem or in conjunction with starting or stopping production.

Chemical use

Today, chemical emissions from forest industry treatment plants are minimal. At pulp mills and sawmills, chemicals are recycled repeatedly in circular flows. Environmentally harmful chemicals are also continuously replaced. This is done through collaboration with the chemical industry and through databases with information on chemicals’ content and effects.