Bio-based products have recycling built-in. They are part of a circular process that starts with photosynthesis. The fantastic thing about forest raw materials is that they are renewable and circular.

Every year, some 650,000 tonnes of packaging is collected at recycling stations across Sweden. That is equivalent to filling the 16,000-seater Avicii Arena in Stockholm from floor to ceiling 28 times. Recycling is about taking care of the Earth’s resources and managing materials responsibly – although the choice of materials to be recycled is just as important as recycling itself.

In Sweden, 80% of paper packaging, 95% of newspaper, and 77% of graphic paper is recycled. You could say that bio-based products have circularity built-in.

How much is recycled?

In Sweden, producers have statutory responsibility for packaging and newspapers. Those who produce and put packaging on the market are responsible for collecting and recycling it. Today, 80% of paper packaging, 95% of newspaper and 77% of graphic paper are recycled in Sweden.

Recycling: a shared responsibility

Many actors influence and help increase recycling rates. Circularity looks different for different products and many actors help enable forest industry products to be recycled. There is now a considerable body of research in this area, and you can read more about it on BioInnovation’s website. (länka)

Wanted: virgin and recycled fibres

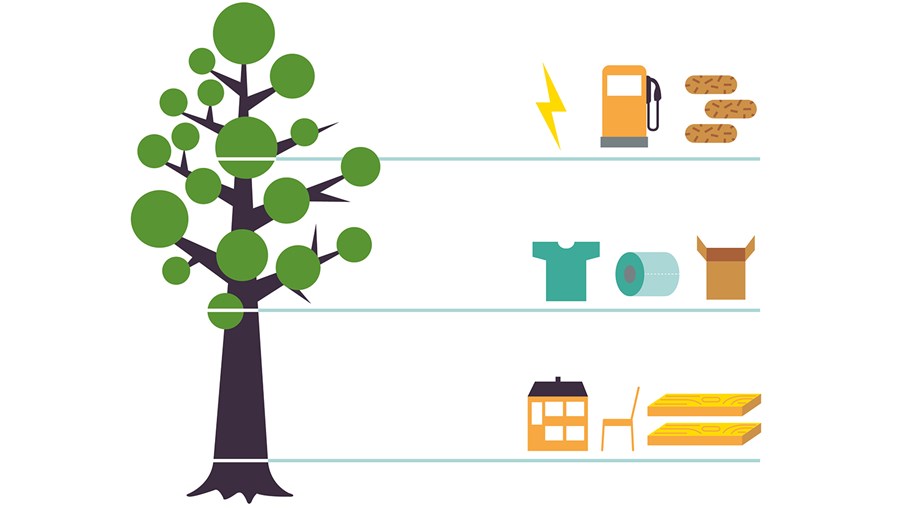

The European forest industry currently uses similar amounts of virgin and recycled fibre. Whether virgin or recycled fibre is used depends on which product is to be manufactured. For example, virgin fibres may be more suitable for certain food packaging and hygiene products. But this does not mean that forests are harvested to become milk cartons. When a tree is harvested, the entire tree is used:

- The strongest part of the trunk becomes timber for buildings and furniture.

- Less substantial parts become pulp for the production of paper, cardboard and textiles.

- Tree tops, branches and residual streams from the forest industry go into products such as bioenergy, biofuels and other chemical applications.

The majority of Swedish wood production is exported. The EU single market is currently the Swedish forest industry’s largest export market, although it has customers all over the world. Among the Nordic countries, Sweden and Finland have substantial amounts of forest, and therefore export a larger proportion of virgin fibre to countries that have less forest land. These countries are in turn able to use this as recycled fibre.