Active forestry, with high growth and the use of products from renewable raw materials, offers long-term climate benefits. However, a key challenge is how to measure substitution effects. To this end, the Swedish Forest Industries Federation is taking steps to develop a standardised and globally accepted method for calculating substitution effects.

In December 2023, after many years of discussion, the EU Commission decided that its new LULUCF regulation would come into effect. The legislation requires net emissions in the EU to be reduced by at least 55 per cent by 2030. Sweden is expected to provide the Union’s largest carbon sink effect with four million tonnes of increased carbon absorption by 2030.

One possible way to increase absorption would be to stop forestry and leave forests untouched, relying entirely on trees’ natural ability to absorb and sequester carbon dioxide. However, Sweden has always argued that this is wrong-headed.

“Seeing forests purely as carbon sinks to solve short-term goals and continue fossil consumption is like cleaning your home by putting all your rubbish in the wardrobe. The major benefit forests have to offer is replacing fossil materials. Because when we talk about forests as carbon sinks, we must remember that forests aren’t entirely stable: they are subject to storms, fire and disease – things that humans can never influence,” says Linda Eriksson, Forest Director, Swedish Forest Industries.

Over the course of their lifetime, trees also absorb carbon dioxide differently. They absorb most during their growth phase, for example. As trees age, growth begins to slow, and thus the storage of new carbon also decreases.

Smart cities could become carbon sinks

By instead using wood in as many applications as possible – construction and furniture making for example – carbon dioxide can continue to be stored. A four-storey wooden house results in a net uptake of 150 tonnes of carbon dioxide equivalents (CO2e), research conducted by Mid Sweden University shows. This also enables more fossil-intensive materials to be phased out.

“When we use wood to construct buildings, for example, the amount of carbon stored increases. If we build in wood, our cities can act as carbon sinks. And we’ll still also need packaging materials, clothes and energy in the future. The climate transition means that we have to stop using fossil materials that produce large carbon loads,” says Magnus Berg, Director Public Affairs, Swedish Forest Industries.

“If we reduce the availability of renewable material, for example by felling fewer trees, achieving the climate transition becomes more difficult because this reduces opportunities for substitution. Reduced harvesting and a more limited market offering make it more difficult for consumers to choose fossil-free alternatives,” Berg adds.

Measurements

The major problem associated with evaluating the climate value of forest products has long been the lack of measurement methods.

“Substitution effects have not previously been properly calculated. We measure emissions, absorption and storage of carbon in forests and land, but we haven’t measured the value of substitution. This has led to a one-sided debate, where we primarily focus on forests’ carbon uptake and the lifespan of forest products, but lose sight of substitution benefits,” explains Berg.

“It’s only when we measure the substitution benefit of long-lived and short-lived products that we can get an accurate picture of its climate effects. We need to be able to measure the climate value of wood and building materials when they are used in packaging and textiles, for example, or completely new areas of use,” Berg adds.

New calculation model for substitution

Torgny Persson, Director of Research and Innovation at Swedish Forest Industries, has been working in close collaboration with researchers and the forest industry for a long time to develop such a calculation model.

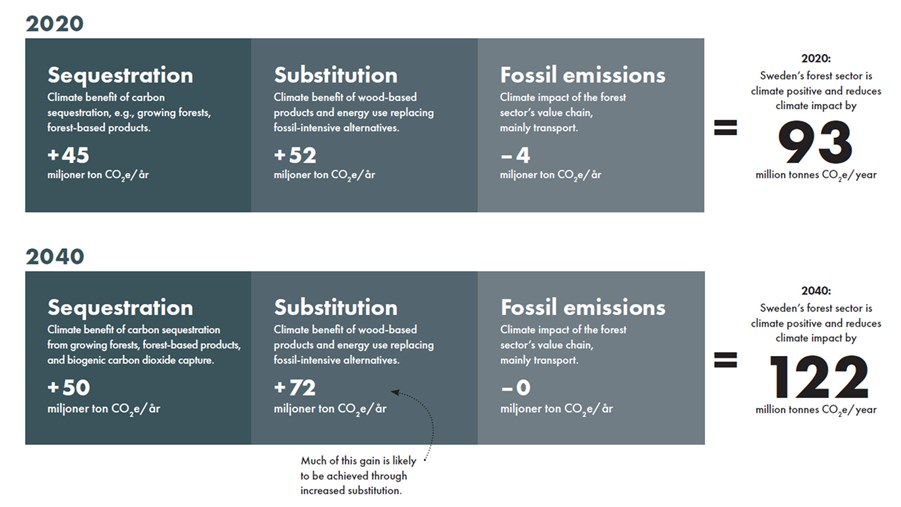

“The model we’ve developed consists of three components, the first of which involves calculating the carbon sequestration effect of wood products. The better we manage our forests, the more growth we get and the more carbon we can sequester in forests in the long term,” Persson says, adding:

“We then try to measure the climate value of substitution. Our ambition is to calculate how much different wood-based products actually contribute to climate benefits. Finally, in the third component [of the calculation], we focus on emissions from our factories and transports.”

The forest industry’s climate benefit. The forestry industry’s annual climate benefit currently amounts to approximately 93 million tonnes of carbon dioxide equivalents (CO2e). The sector’s ambition is to increase this climate benefit by 30 per cent, to 122 million CO2e by 2040. Much of this gain is likely to be achieved through increased substitution.

Method set to become a standard

The goal of the Swedish forest industry is to increase carbon sequestration by 30 per cent and substitution by 20 million tonnes a year by 2040 from 2020 levels.

“Our model is an important tool in achieving this. It’s also now becoming a standard for how the forest industry worldwide calculates climate benefit. We expect to complete work on standardisation in 2025,” says Persson and concludes:

“Increased resource efficiency includes the use of waste, such as ashes and different types of sludge. We’re intensifying work in this area to identify solutions for how this waste can be converted into products. Waste from other industries, such as textile scraps, can also become inputs in our production and thus contribute to more resource-efficient and circular use of raw materials and materials.”

Considerable interest in the storage of biogenic carbon dioxide

Considerable interest exists in the forest industry in the capture and product extraction of biogenic carbon dioxide.

“Biogenic carbon dioxide may ultimately become a new raw material. But capturing carbon dioxide is a process that in itself needs large amounts of energy and more research,” says Torgny Persson, Director of Research and Innovation at Swedish Forest Industries.

Much research interest is currently focused on the potential of collecting and storing biogenic carbon dioxide found in forest industry factories.

“The hope is to be able to capture carbon dioxide from factories and then store it, perhaps in exhausted North Sea oil wells, or even better: make new products from carbon. However, more research is needed before that is possible,” says Persson.